High-tech Evaluation Could Help Improve Low-tech Masks

Nanotechnology may not be the first thing people think of when sewing a homemade face mask, but it may help make home-sewn masks more effective. As the need to wear face coverings as a public health precaution becomes a new normal, nanofabrication experts at the UC San Diego Qualcomm Institute (QI) are working together with the community to examine the efficacy of improvised masks using scanning electron microscopy.

When the shortage of personal protective gear prompted numerous efforts to produce and share improvised face masks, QI researchers saw the need for quality assurance and recognized that QI’s nanotechnology facility Nano3 was in a unique position to help fill that need.

“This came about organically as efforts in the community began looking for ways to respond,” said Ramesh Rao, Director of QI. “We wanted to figure out the best way to use our capabilities. We had a skeletal crew still on site. We had the machine. This was something we could do that was not happening in the community.”

The machine in question is a scanning electron microscope capable of taking images at a microscopic level to gain information about the composition and topology of sample materials – in this case, fabric for face masks donated by volunteers actively sewing masks for the community. By imaging structures with dimensions potentially much smaller than the coronavirus, researchers can begin to judge a material’s effectiveness in blocking the spread of the virus. While pore size is one measure of effectiveness, other factors, such as a fabric’s ability to wick or absorb moisture, also contribute to or detract from a mask’s usefulness, complicating the evaluation process.

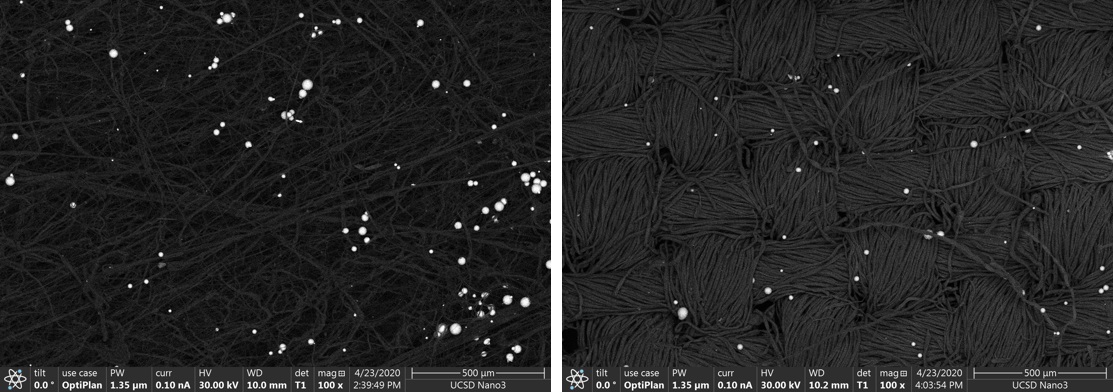

“Although we can qualitatively see gaps in the fabric, we wanted to test if particles were making their way through,” said Ryan Nicholl, a microfabrication and electron microscopy engineer for Nano3.

To further test the fabrics, Nicholl and his colleague Jeff Wu, senior nanfabrication engineer for Nano3, built a small contraption to simulate a mask in use, which is helping them better understand the filtering capacity of the samples sent to them. The “sneeze rig” holds the fabric in place over a silicon slide, and a suction device simulates the breathing of someone wearing a mask. On the opposite side of the fabric, a spray with suspended nanoparticles that are either the size of the virus or the size of water droplets is spritzed onto the fabric, mimicking a sneeze from a bystander. The slide is then imaged, and tests are run to count the number of particles per area that make it through the fabric and onto the slide.

This simple test is being used to evaluate a variety of off-the-shelf fabric as well as medical-grade N95 masks, which are used as a comparison. Nicholl notes that there are several standards that need to be met before a mask qualifies as medical grade, and particle filtration is only one of them. The tests currently being conducted mostly serve as a calibration effort. However, the results could eventually help guide the quality of improvised masks for those making them and for everyone using them.

“Going forward, there could be initiatives where people try to fabricate masks with novel or new materials,” said Nicholl. “Once we have our methodology straight and have compared known materials, we will have a better reference for standards.”

Media Contacts

Alicia Clarke

858-275-7978

amclarke@eng.ucsd.edu