Hi-Tech Tools Facilitate Specimen Preparation at UCI

|

07.05.06 -- Researchers using the Carl Zeiss Center of Excellence at Calit2@UCI recently got some state-of-the-art assistance.

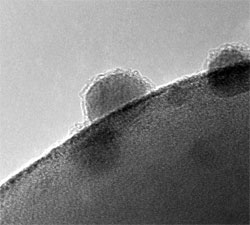

Six specimen-preparation tools were donated to the lab by South Bay Technology, Inc., a Southern California materials-preparation manufacturing company. The equipment will be used to prepare SEM cross sections, deposit high-resolution films onto samples, and clean samples and/or microscope parts. It is valued at more than $125,000.

“These instruments represent the latest in materials processing equipment and will provide the users with a broad range of technologies,” says South Bay Technology President David Henriks. “The idea here is not to limit the researchers to tools that may have been acquired years ago for a different purpose.”

The donated equipment includes a lapping and polishing system, a lapping fixture, a tripod polisher, a low-speed diamond-wheel saw, an ion-beam sputter-deposition and etching system, and a plasma cleaner.

“If you’re trying to drive a nail into a piece of wood and all you have is a screwdriver, you won’t be very effective,” says Henriks. “We have the tools to allow researchers to be effective in processing their samples for analysis. Our goal with the Calit2 partnership is to always have the proper equipment available for the job.”

|

||||

In addition to assisting Calit2 researchers with their specimen preparation, the SBT/Calit2@UCI partnership provides other opportunities. The company’s headquarters and manufacturing facility are located in San Clemente , and the lab’s proximity allows SBT to respond quickly to new materials preparation challenges as well as demonstrate the efficiency of their equipment to new customers.

“Zeiss manufactures outstanding instruments and their performance is limited only by the quality of the specimen being imaged. South Bay Technology provides a means to improve sample quality, which then allows customers to exploit the technology in the Zeiss tools,” says Henriks.

He adds: “We’re very excited about the possibilities this partnership presents. It is a win-win-win situation for South Bay Technology, UCI and Zeiss. I am looking forward to a mutually beneficial partnership and I foresee more rapid development of materials processing tools that could change the face of materials research.”