UC San Diego-based iBotics Team Competes in Underwater Unmanned Vehicle Competition

By Tiffany Fox, (858) 246-0353, tfox@ucsd.edu

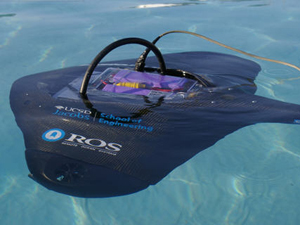

San Diego, CA, Aug. 12, 2008 -- They've coped with leaks, navigation problems and a few minor explosions, but the San Diego iBotics team — based at UC San Diego and funded by the Jacobs School of Engineering — had the most beautiful underwater craft in this year's competition of the Association for Unmanned Vehicle Systems International (AUVSI). Their sleek, carbon-fiber entry, dubbed the “Stingray,” features a lightweight shell that resembles a small stingray and provides very little drag.

|

"A lot of teams in the competition can be very successful with a Tupperware can, a little computer and two thrusters,” said San Diego iBotics team president Gideon Prior, a Ph.D. student in electrical engineering at UC San Diego. “We've kind of outdone ourselves making this biomimetic, hydrodynamic vehicle with really novel propulsion capabilities. It gives us a lot of cool points, but making it work has been kind of a black magic that we had to figure out. We started by designing the hull and choosing a novel propulsion system, and then went backwards and tried to figure out how to control the thing."

After failing to make the semi-finals in 2007, the team finished in the top half, placing 11th out of 25 teams from around the world in the 2008 competition. The Stingray beat out unmanned vehicles from the University of Southern California, Georgia Tech and Japan's Kyushu Institute of Technology. The top three winners in the competition were the University of Maryland, the University of Texas at Dallas and the École de Technologie Supérieure, based in Quebec. A team from San Diego City College placed 10th.

The action took place over three days earlier this month in a large pool at the Space and Naval Warfare System Center's TRANSDEC Facility, located on the cliffs above the Pacific, just north of the Point Loma Lighthouse. In keeping with the theme for this year's competition -- "Underseas Eleven," a play on the film "Oceans Eleven" -- the TRANSDEC pool was converted to a high-stakes casino, where teams had to use vision recognition software and navigational algorithms to maneuver their vehicles past underwater "slot machines" and "blackjack tables" and into a narrow air duct, where an acoustic pinger pointed the way to the casino's "safes." Teams had to follow the pinger, retrieve the safes and make their way to the “rooftop” (i.e. a PVC octagon at the water's surface) to make their getaway.

The iBotics team certainly wasn't hedging its bets in this competition, having taken extra measures to make the craft more water-tight and improve its maneuverability. Of crucial importance this year were the Stingray's "servos" or servomotors — small motors whose position can be precisely controlled and are used to change the attitude of the hydrofoils in the propulsion system. Prior says the servos kept leaking during last year's competition, leading the team to spend quite a bit of time and money this year on improving their reliability. The solution proved to be low-tech but quite effective: The servos themselves were wrapped up in multiple latex plastic bags and were zip-tied and epoxied around the motor shaft. The team also got a little waterproofing help from their friends at UCSD's Scripps Institution of Oceanography.

|

"They custom-built a water-tight lid for the electronics housing in exchange for two cases of beer," laughed Prior. "They were very cool to us. They were even offering to make it out of titanium!"

To improve the craft's propulsion and maneuverability, Prior and his team equipped the Stingray with two Voith-Schneider propellers (VSPs), which are mounted on the hull bottom and allow the craft to maneuver on a horizontal plane. The VSPs consist of a rotating ring of hydrofoils that can be precisely oriented as it spins providing thrust in any direction in a plane be it forward or backward, turning in place or strafing from side-to-side.

Explained Prior: "What's really neat about these things is that you can get a force vector in any direction you want. People use these for tugboats, but they’ve recently become popular among radio-control boat hobbyists. We're the first ones I'm aware of who have ever used these for an underwater vehicle. With the VSPs, the Stingray can behave just like a helicopter, only underwater.”

Aside from its eye-catching design, the iBotics craft is also equipped with forward- and down-looking cameras, a high-intensity lighting apparatus, a piezoelectric film-based sonar system (typically found in acoustic-electric guitar pick-ups), inertial navigational sensors and custom-designed software, all of which was written in C and C++ programming languages, and runs in Ubuntu-based Linux distribution. A dockside control station (DCS) works in a client-server configuration with the Stingray as server and the DCS as client, and all communication is done over standard TCP/IP connections.

Next year the team plans to forego any more work on the mechanical design and instead look into making the Stingray, which currently weighs 22 pounds, slightly larger. "Its compactness is its downfall. We get a lot of points for our low weight, but it is hard to get everything we need into such a small space," Prior said.

It would also be nice, he added, if it didn't explode during next year's test runs (as it did this year).

"We use lithium polymer batteries and lithium explodes when it gets wet. Several times, it looked like a small bomb went off in our computer case. We successfully transformed several hundred dollars worth of motor controllers into soot."

|

Explosions or no, Prior said the AUVSI event is well worth the long hours his team has put into making the Stingray seaworthy and ready for competition

"This competition is multi-purposed," Prior observed. "The primary benefit for the autonomous robotics community is the development of ‘extremely autonomous robots’. Unlike ground and air vehicles, underwater environments prohibit the use of the traditionally most relied upon sensors: GPS and Laser Radar (LADAR). To boot, vision works poorly, if at all, and communication with the vehicle is difficult, as radio-frequency communication is very limited. Tackling these challenges not only contributes to the advancement of underwater vehicles, but to furthering the robustness of all autonomous robotic platforms.

“In addition, a big thing for me has been networking with students from all over the world. Even though this is a competition, there's been nothing but support. All the teams are cheering for each other. Our hydrophones weren't working very well and the team from North Carolina State said they had some lying around, and we had people writing code for other people. Everyone's pulling for one another."

"The autonomous robot community is pretty small so this is a good opportunity to meet all the up-and-comers in the industry," he continued. "Almost all of us have had job offers. I feel like we're advancing our understanding of how real engineering problems get solved. This process has been astounding, and something I've never been able to learn in a classroom on a whiteboard. It comes from pounding your head against a keyboard for hours and hours at a time before serendipity strikes and you figure out what the problem is. It's really good real-world experience for students who have never seen anything like this. "

Media Contacts

Tiffany Fox, (858) 246-0353, tfox@ucsd.edu

Related Links

San Diego iBotics

Association for Unmanned Vehicle Systems International (AUVSI)

Jacobs School of Engineering